A12/802, Karishma Society, Kothrud, Pune - 411038

Shed Number 18, GAT Number 391/1, Gauddara, Taluka - Haveli, PUNE - 412205

Top‑quality biomass pellets deliver superior calorific value and clean combustion performance.

Convert agricultural and wood residues into eco-friendly energy while supporting rural communities and reducing waste.

Offer adaptable pellet feedstocks—hardwood, softwood, coffee husk, cashew shell—to meet diverse customer energy needs.

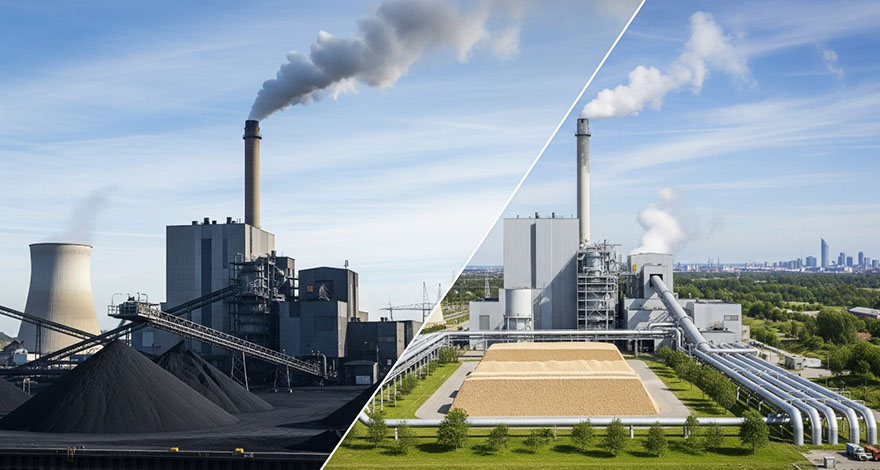

Drive low‑emission biomass adoption aligned with India’s co‑firing mandates and environmental stewardship goals.

Co‑firing Mandate

MTPH Subsidy

Production Units

Crafted from dense deciduous woods like oak, beech, and birch, Hardwood Pellets deliver a steady and long-lasting burn thanks to their high lignin.

Made from resin-rich softwoods such as pine, spruce, and fir, Softwood Pellets ignite easily and burn hotter and faster—heat output around 17–20 MJ/kg

Our Custom Pellets blend agricultural residues like coffee husk, corn cob, and cashew shell, tailored to your technical requirements and sustainability goals.

High‑density pellets burn cleanly and deliver consistent, high-output heat with minimal ash and smoke.

Made from renewable wood waste, biomass pellets offer near carbon‑neutral heat with lower emissions.

At Aspen Energy, we are committed to delivering premium biomass pellets that combine high calorific value with eco-friendly production processes. Our state-of-the-art facility in Pune ensures consistent quality and timely delivery, meeting the diverse energy needs of both domestic and international markets.

Our biomass pellets boast a gross calorific value of 4300–4500 Kcal/Kg and an ash content of just 1–2%, ensuring efficient combustion and minimal residue. This makes them ideal for industrial boilers, power plants, and residential heating systems,

In addition to hardwood and softwood pellets, we offer custom biomass pellets made from agricultural residues like coffee husk, corn cob, and cashew shells. This versatility allows us to cater to specific client requirements, promoting waste utilization.

Discover how Aspen Energy delivered measurable energy efficiency and sustainability success.

Studstrup Power Station, operated by Ørsted in western Denmark, transitioned Units 3 & 4 from coal to wood pellets between 2014 and 2016. This landmark shift enabled combined heat & power (CHP) generation while leveraging biomass for cleaner, renewable energy.

700 MWe electricity capacity

2014–2016 from coal to pellets

65,000 ton pellet silo

Supplies heat and power to the Århus district heating network

Built on a former steelworks site near Rotherham, Templeborough Power Station became operational in 2018 using locally produced wood pellets. It generates electricity and heat for the National Grid, showcasing large-scale sustainable energy repurposing.

44 MW generation capacity

270,000 ton/year wood pellets processed

Powers roughly 78,000 UK homes

150,000 tonnes avoids CO₂ emissions annually

Inyenyeri provides locally made wood pellets, sold alongside leasing of efficient Mimi Moto cook stoves. This program aims to reduce reliance on charcoal and improve household energy access through cleaner, affordable fuel systems.

800 tonnes/year pellet supply chain

Served 1,000 households by 2016

Stove+fuel model cost‑competitive with charcoal

Includes free delivery, repairs, and user training

We source sawdust, wood chips and agricultural residues (e.g. rice husk, corn cob), ensuring clean, contaminant-free biomass for pellet production.

Feedstock is pulverized into uniform fine particles and dried to ~10–15% moisture using industrial dryers, optimizing combustion efficiency.

High-pressure and heat compress the conditioned biomass through a die, using natural lignin as binder to form durable 6–8 mm pellets.

New pellets are cooled to solidify structure, screened to remove fines, then packed in bags or bulk for safe storage and delivery.

Softwood pellets generally burn hotter, ignite faster, and produce less ash due to higher resin content—often delivering 10–20% more BTU per pound compared to hardwood. Hardwood burns longer and steadier, but may produce slightly more residue.

Yes—softwood pellets typically generate less ash and fewer airborne particles than hardwood, reducing cleaning effort and improving combustion efficiency.

They can—but mixing may affect burn rate and combustion. Performance is more influenced by pellet quality (moisture content, uniformity) than the species alone.

Pellet Energy is the epitome of excellence in the biomass industry. Their pellets burn efficiently and cleanly, and their ethical manufacturing is truly impressive.

Customer

Our partnership has been outstanding. Their products meet demanding specifications and they readily customize orders. Customer satisfaction is apparent in every interaction.

Customer

“Impressed with timely, proper delivery of high-quality 6 mm biomass pellets in PP bags—exactly matching our requirements."

Customer

Exceptional groundnut-shell briquettes—unsurpassed quality and specifications. A go-to supplier for bulk biomass fuel needs.

Customer

Our long-term partnership built on trust—willingness to customize and unwavering commitment to quality make them reliable allies.

Customer

Switching to biomass pellets can cut your fuel costs by up to 30% while lowering emissions and improving operational efficiency.

WhatsApp us